TL;DR: Dimensional accuracy in auto body repairs is critical for vehicle safety, performance, and aesthetics. Accurate tools, maintained through regular calibration and inspections, ensure precise measurements, reduce errors, and enhance quality. This includes structured schedules for checks, specialized training, thorough inspections, and reliable documentation, all contributing to higher-quality dimensional accuracy repair and increased customer satisfaction.

In the realm of precision manufacturing, achieving accurate dimensional control is paramount. This introduction delves into the vital aspect of calibration within the context of dimensional accuracy repair tools. Understanding how minute variations impact final products underscores the importance of regular calibration for maintaining tool precision. We explore best practices to ensure optimal performance, highlighting the significance of consistent calibration as a cornerstone in the pursuit of flawless dimensional accuracy repairs.

- Understanding Dimensional Accuracy and Its Impact

- The Role of Calibration in Ensuring Precision

- Best Practices for Regular Calibration and Maintenance

Understanding Dimensional Accuracy and Its Impact

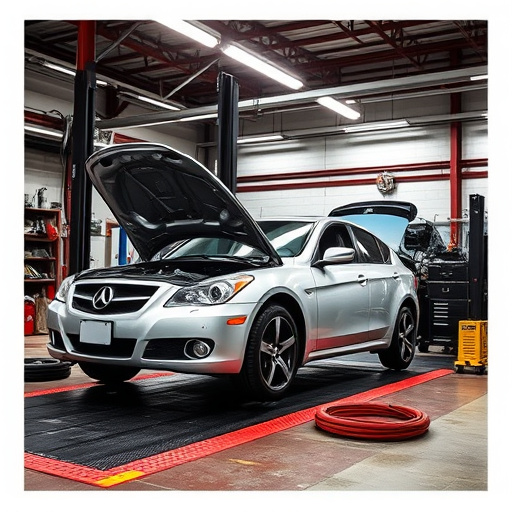

Dimensional accuracy is a critical aspect of any manufacturing or repair process, especially when it comes to ensuring the quality and safety of vehicles in an auto body shop or car body shop. It refers to the level of precision with which measurements are taken and compared against established standards, allowing for consistent and reliable results. In the context of dimensional accuracy repair tools, understanding this concept is paramount. Every component of a vehicle, from panels to frames, must fit perfectly to maintain structural integrity, aesthetic appeal, and overall performance—a task that relies heavily on accurate measurements.

When dimensions are off by even a slight margin in auto body work or car bodywork, it can lead to significant issues. Inaccurate repairs may result in poor fitting parts, compromising the vehicle’s safety and reliability. Furthermore, it can negatively impact the final finish, creating an unappealing appearance that requires additional time and effort to rectify. Thus, maintaining high standards of dimensional accuracy is not just a matter of precision but also ensures the effectiveness and efficiency of repair processes in car body shops, ultimately contributing to customer satisfaction and the longevity of vehicles.

The Role of Calibration in Ensuring Precision

Calibration plays a pivotal role in ensuring the precision and reliability of dimensional accuracy repair tools used in various industries, including automotive sectors like auto body work and car restoration. It is a meticulous process that involves adjusting and fine-tuning these instruments to deliver accurate measurements each and every time they are employed. Without proper calibration, these tools can exhibit drift or deviation over time, leading to inaccurate repairs, particularly in intricate tasks such as automotive collision repair.

Imagine a scenario where a dimensional accuracy tool used for measuring car body panels is not calibrated correctly. This could result in inconsistent measurements, causing issues during the restoration process. Calibration ensures that every repair tool operates at peak performance, enabling technicians to make exacting adjustments and repairs across different components—from car frames to intricate trim pieces—thus contributing to the overall quality of auto body work and ensuring customer satisfaction.

Best Practices for Regular Calibration and Maintenance

Regular calibration and maintenance are paramount for ensuring the longevity and optimal performance of dimensional accuracy repair tools. Establish a structured calendar for checks and adjustments to account for any drift or wear over time. This process should involve thorough inspections, including benchmarking against established standards and reference materials. All calibrations should be documented, detailing the methods, equipment used, and any deviations or corrections made.

Implementing best practices requires a dedicated team equipped with specialized training in calibration procedures. For automotive body shop services offering frame straightening and car paint services, regular calibration ensures precise measurements, minimizing errors during repairs. Consistent maintenance not only guarantees device reliability but also extends the lifespan of these critical tools, ultimately contributing to higher-quality dimensional accuracy repair.

Calibration is an indispensable practice for maintaining dimensional accuracy in repair tools, ensuring that measurements are reliable and precise. By regularly calibrating equipment, professionals can guarantee the integrity of their work, meet quality standards, and ultimately provide superior services within the dimensional accuracy repair field. This consistent attention to calibration is key to fostering trust and satisfaction among clients who rely on accurate repairs.