Dimensional accuracy repair in automotive body shops addresses human errors, inconsistent measurements, and subpar equipment, preventing misalignments and imperfections. It involves meticulous measuring and adjustment of vehicle components to meet manufacturer standards, aiming for a seamless finish. Achieving and maintaining long-term dimensional accuracy through best practices ensures quality workmanship and customer satisfaction.

In the realm of precision engineering and manufacturing, achieving and maintaining dimensional accuracy is paramount. However, various factors can lead to deviations, requiring a meticulous repair process. This article elucidates the critical steps involved in addressing dimensional accuracy issues, offering a comprehensive guide for professionals. From understanding the problems to implementing a structured repair methodology, we provide an in-depth overview. Moreover, best practices are highlighted to ensure long-term accuracy, making this a go-to resource for those seeking to optimize their dimensional accuracy repair protocols.

- Understanding Dimensional Accuracy Issues

- Step-by-Step Repair Process Overview

- Best Practices for Ensuring Long-Term Accuracy

Understanding Dimensional Accuracy Issues

Dimensional accuracy issues in automotive body shops, or collision repair centers, can arise from various factors, leading to misalignments and imperfections in vehicle repairs. These problems are often a result of human error, inconsistent measurements, or the use of subpar equipment during the auto painting process. In an industry where precision is key, ensuring dimensional accuracy is vital to the overall quality of the repair.

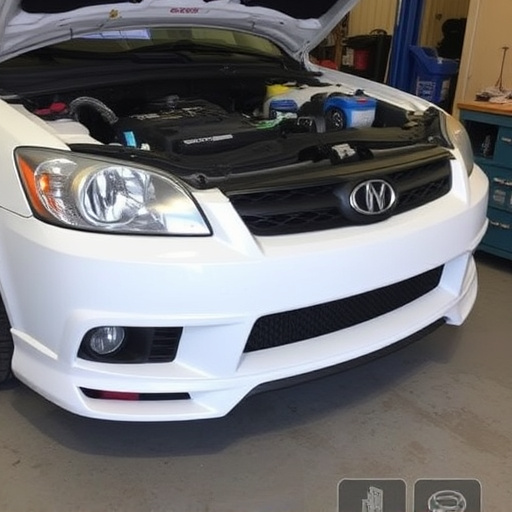

When vehicles suffer damage, whether from accidents or minor dents, restoring them to their original specifications requires meticulous attention to detail. Dimensional accuracy repair involves carefully measuring and adjusting various components of the vehicle body to match the manufacturer’s standards. This may include realigning panels, correcting cracks, or fine-tuning the overall structure to ensure a seamless finish when the auto painting process is complete, creating an aesthetically pleasing and structurally sound automobile at the collision repair center.

Step-by-Step Repair Process Overview

The process of achieving dimensional accuracy in repairs, particularly for automotive bodies like those seen at an auto collision center, involves several meticulous steps. It begins with a thorough inspection to identify the extent of the damage and assess the level of precision required. This initial phase is crucial as it determines the repair techniques and materials needed for optimal results.

Once the assessment is complete, the actual repair work commences. For car paint repair or even paintless dent repair, skilled technicians employ specialized tools and methods. These can range from manual techniques to advanced technology, ensuring every imperfection is addressed. The goal is to match the original dimensions and finish seamlessly, making it nearly impossible to distinguish the repaired area from the rest of the vehicle’s body.

Best Practices for Ensuring Long-Term Accuracy

Maintaining long-term dimensional accuracy is paramount for any collision repair shop or dent repair service provider. To ensure sustained precision, several best practices should be implemented as part of the regular workflow. Firstly, using high-quality tools and equipment calibrated regularly guarantees accurate measurements and seamless repairs. Advanced training for technicians on the latest repair techniques and technology ensures consistent outcomes, minimizing human error.

Additionally, proper documentation and record-keeping are vital. Detailed records of each repair job, including before-and-after measurements, photos, and notes, serve as a valuable reference for future work. Regular inspections and quality control checks at every stage of the repair process help identify and rectify any deviations from the original specifications promptly. Adhering to these best practices not only guarantees superior car bodywork repairs but also ensures the longevity of dimensional accuracy in every dent repair service provided.

The journey towards achieving optimal dimensional accuracy involves understanding the root causes of issues, implementing a structured repair process, and adopting best practices. By systematically addressing misalignments, utilizing advanced tools, and maintaining regular calibration, professionals can ensure long-term precision in their measurements. Embracing these strategies empowers organizations to streamline operations, enhance product quality, and foster trust in their data, ultimately elevating the overall reliability of dimensional accuracy repair efforts.