Dimensional accuracy repair is vital in the automotive industry for restoring vehicles affected by frame, panel, or suspension damage to their original dimensions and structural integrity. Technicians perform visual inspections and use tools like laser scanners and digital calipers to measure damage accurately. Repairs range from paint services to extensive body work, ensuring safety features, aesthetic appeal, and longevity. Advanced techniques including 3D scanning, manual methods, and CAD software combine for top-tier dimensional accuracy repairs, restoring vehicles to pre-incident condition.

In the automotive industry, maintaining precise dimensional accuracy is paramount for vehicle safety and performance. When damage occurs to frames, panels, or suspensions—from accidents or routine wear—it can negatively impact a car’s overall alignment and handling. This article delves into the critical aspect of dimensional accuracy repair, offering a comprehensive guide. We explore effective strategies for identifying and rectifying frame, panel, and suspension damage, ensuring vehicles return to their optimal dimensional state.

- Understanding Dimensional Accuracy Repair

- Identifying Frame, Panel, and Suspension Damage

- Effective Strategies for Dimensional Accuracy Repair

Understanding Dimensional Accuracy Repair

Dimensional Accuracy Repair is a critical process that ensures vehicles affected by frame, panel, or suspension damage are restored to their original dimensions and structural integrity. This meticulous technique is essential in the automotive industry, especially after car collisions, as it plays a pivotal role in safe and effective car collision repair. Body shop services specializing in this repair method employ advanced tools and techniques to accurately measure and adjust damaged components, ensuring they fit seamlessly with the vehicle’s overall structure.

The primary goal of dimensional accuracy repair is to maintain the vehicle’s safety features, aesthetic appeal, and overall performance. Unlike paintless dent repair methods, which focus on removing dents without painting, dimensional accuracy repair addresses the underlying structural issues. This meticulous approach guarantees that every part of the car, from the frame to the suspension systems, aligns perfectly, enhancing both the vehicle’s functionality and longevity.

Identifying Frame, Panel, and Suspension Damage

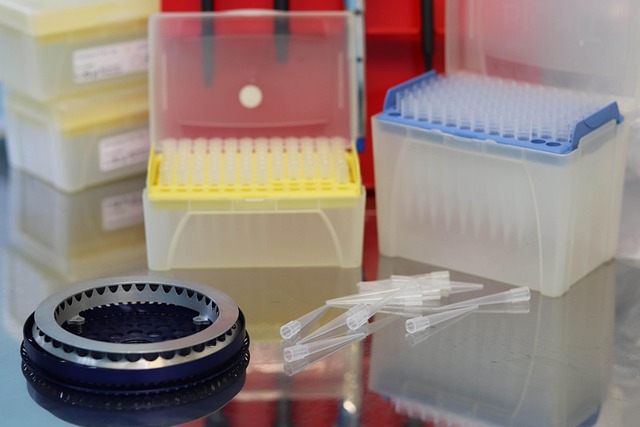

Identifying frame, panel, and suspension damage is a critical step in ensuring accurate dimensional accuracy repair. Visual inspections are often the initial point of evaluation, where skilled technicians look for signs of distortion, misalignment, or visible deformities. These can include dents, scratches, creases, or any asymmetries in the vehicle’s body panels. Dimensional measurement tools, such as laser scanners and digital calipers, are then employed to quantify the extent of the damage. These instruments capture detailed 3D data, providing precise dimensions and allowing for a comprehensive analysis.

Proper identification involves examining not just the visible surfaces but also checking for any underlying structural issues. This might include looking at the integrity of the frame, checking for loose or broken components in the suspension system, and assessing the alignment of wheels and tires. With these insights, technicians can determine whether the damage is superficial or impacts the overall structural integrity, guiding the extent and approach of the dimensional accuracy repair, be it through car paint services, bumper repair, or extensive automotive body work.

Effective Strategies for Dimensional Accuracy Repair

Achieving precise dimensional accuracy during repairs is paramount for ensuring the structural integrity and aesthetic appeal of vehicles, especially after an automotive collision repair or dent repair. This involves employing advanced techniques to measure and adjust components like frames, panels, and suspensions to their original specifications. One effective strategy is utilizing specialized measuring tools such as 3D scanners, which capture detailed digital profiles of damaged areas, providing a baseline for precise repairs.

Additionally, experienced technicians employ manual methods, combining traditional skills with modern technology. This includes using precision instruments to gauge and adjust parts, along with computer-aided design (CAD) software that facilitates the visualization and modification of components in a virtual environment. By combining these approaches, automotive collision repair experts can deliver top-tier dimensional accuracy repairs, ensuring vehicles return to their pre-incident condition, enhancing safety and customer satisfaction.

Dimensional accuracy repair is an essential aspect of vehicle restoration, ensuring that frames, panels, and suspensions maintain their original integrity. By understanding the causes and implementing effective strategies, such as using advanced technology for measurement and precise tooling for repairs, auto enthusiasts can achieve remarkable results. This process not only enhances the structural soundness but also preserves the vehicle’s overall aesthetic value, making it a valuable skill to master in the world of automotive restoration.