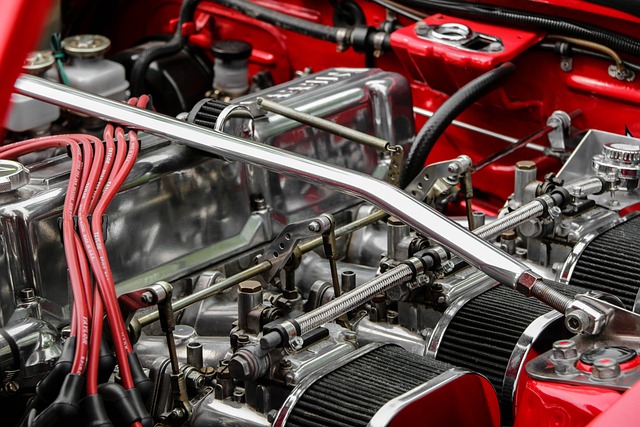

Dimensional accuracy repair involves meticulous manual techniques historically dominant in industries like automotive collision repair and car damage restoration due to their precision. Skilled technicians use specialized tools for tasks such as dent removal, panel straightening, and alignment. However, these methods are time-consuming and prone to human error. Automated solutions, leveraging robotics, CAD, and machine learning, are emerging as a game-changer, streamlining the process, offering consistency, and reducing manual labor needs while still requiring human validation for guaranteed precision.

In the realm of data management, achieving precise dimensional accuracy is paramount for effective decision-making. This article delves into the comparative analysis of two primary approaches: Traditional Manual Dimensional Accuracy Repair and Automated Dimensional Accuracy Repair Techniques. We explore the nuances of each method—from manual data cleaning, human involvement, and time consumption to automated systems’ advanced algorithms, machine learning models, and efficiency gains. Understanding these techniques empowers organizations to make informed choices, enhancing overall data quality and decision-making processes.

- Traditional Manual Dimensional Accuracy Repair: Step-by-Step Process

- – Overview of manual methods

- – Manual data cleaning and preparation techniques

Traditional Manual Dimensional Accuracy Repair: Step-by-Step Process

In traditional manual dimensional accuracy repair, the process begins with a thorough inspection of the damaged area. Skilled technicians use specialized tools to measure and assess the extent of misalignment or deformity in various components, such as panels, frames, and glass. This meticulous step-by-step approach involves marking the damage, removing affected parts if necessary (like a bumper repair in car collision repair), and then carefully realigning and replacing them. Each adjustment is made with precision to ensure that all dimensions align perfectly, restoring the vehicle’s structural integrity.

Technicians then employ various techniques like welding, riveting, or adhesive bonding to secure the repaired parts. Post-repair, another round of inspections is conducted to verify dimensional accuracy. This rigorous manual labor ensures that not only is the damage visually corrected but also meets the required specifications, preventing future issues. While effective, manual methods rely heavily on human expertise and can be time-consuming, especially for complex car collision repairs.

– Overview of manual methods

In the realm of dimensional accuracy repair, manual methods have long been the standard practice, particularly in industries such as automotive collision repair and car damage restoration. These techniques involve meticulous, hand-driven processes where skilled technicians use specialized tools to measure, adjust, and refinish components to their original specifications. From dent removal and panel straightening to complex alignment tasks, manual labor ensures precise control over every adjustment, making it ideal for intricate or delicate repairs. Technicians employ a variety of calipers, gauges, and other precision instruments to gauge dimensional changes, enabling them to make incremental adjustments until the affected area regains its original dimensions.

Despite their precision, manual methods come with drawbacks, such as time-consuming nature and potential human error. In today’s fast-paced world, where efficiency is paramount, automated dimensional accuracy repair techniques are gaining traction in both collision repair and dent removal processes. Automation leverages advanced technologies like robotics, computer-aided design (CAD), and machine learning algorithms to streamline the repair process, minimizing human intervention and maximizing consistency. These automated systems can swiftly scan and analyze damage, identify affected areas, and precisely apply repairs, be it for car damage restoration or complex collision repair scenarios.

– Manual data cleaning and preparation techniques

Manual data cleaning involves a meticulous process where skilled professionals inspect and correct errors one by one. This technique is akin to an artisan carefully restoring a classic car, focusing on intricate details. It requires a deep understanding of the data’s context and domain knowledge to make informed decisions. In the realm of dimensional accuracy repair, manual techniques are crucial for handling complex anomalies and outliers that automated systems might struggle with. Data analysts or domain experts meticulously review and validate each correction, ensuring precision.

In contrast, Automated dimensional accuracy repair leverages advanced algorithms and machine learning models to streamline the cleaning process. It’s like a highly skilled mechanic using modern tools for efficient car body restoration, fixing dents and cracks promptly. These automated systems can handle vast datasets, identifying patterns and anomalies with remarkable speed. However, they might not always capture nuanced issues, requiring human oversight to ensure the quality of repairs, much like an auto bodywork expert fine-tuning their work for perfection.

In comparing manual versus automated dimensional accuracy repair techniques, it’s evident that each approach presents unique advantages. While traditional manual methods offer precision and granular control, they are time-intensive and prone to human error. Automated solutions, leveraging advanced algorithms and machine learning, streamline the process, significantly reducing effort and potential mistakes. Ultimately, the choice between these techniques depends on factors like data complexity, available resources, and desired turnaround time. Organizations seeking efficient and accurate dimensional accuracy repair should seriously consider implementing automated tools, which can revolutionize their data management strategies.